Basic Info.

Model NO.

RH1000

HS Code

9031809090

Production Capacity

1000/Month

Product Description

Introduction:

RH1000 online monitoring station consists 16 vibration and temperature optional channels, 2 process information channels, 1 speed channel. Taking advantage of the patent of RONDS, it can realize synchronous data acquisition with all channels.

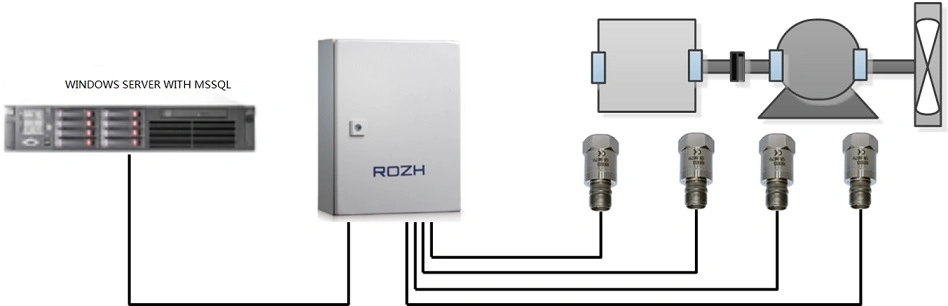

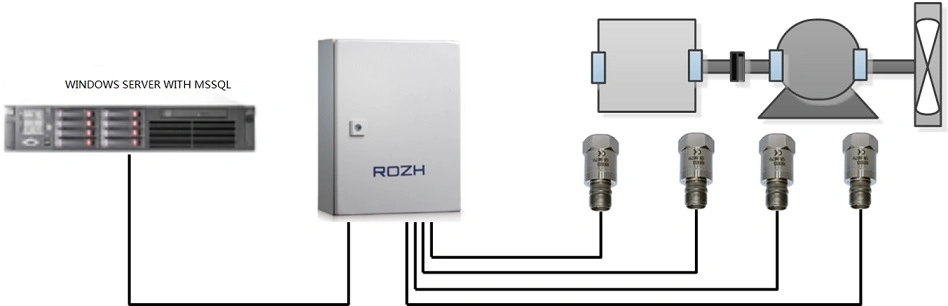

Working Diagram:

System Features: RH1000 online monitoring station consists 16 vibration and temperature optional channels, 2 process information channels, 1 speed channel. Taking advantage of the patent of RONDS, it can realize synchronous data acquisition with all channels.

Working Diagram:

- Maximal 16 channels synchronous data acquisition

- Machine Data Overview

- DAQ Definition Group Management & Characteristic Parameter Group Management

- Configuration Information Tree

- Remote Data Viewing

- Plenty of Data Analysis Tools

- Automatic Calculation of Characteristic Frequency

- Intelligent Alarm Function

- Create report Function

Technical Parameters

| Max.channels | 16 channels vibration/temperature, 1 channel speed, 2 channels processing | |

| Vibration(temperature measurement is optional) | ||

| Channel No. | 16 channels | |

| Sensor integrated | IEPE acceleration sensor | High/ low frequency and dual acceleration acquisition synchronously |

| Input impedance | 200kΩ | |

| Input coupling | AC | |

| Sensor drive current | 4mA@24V | |

| A/D converter | 24 bits delta-sigma ADC | |

| 256Hz,512Hz,1280Hz,2560Hz,5120Hz, 12.8KHz,25.6KHz,51.2KHz,102.4kHz | ||

| Dynamic range | 100dB | |

| Signal range | -10~10V | |

| Precision | ±1%,160Hz | |

| Frequency response | 0.2dB(10Hz ~ 5kHz) 0.6dB(2Hz ~ 20kHz) | |

| Integrated temperature measurement | Support | |

| Temperature measurement range | -40ºC ~ 120ºC | |

| Temperature measurement range | ±2ºC | |

| Speed channel | ||

| Channel No. | 1 channel | |

| Sensor integrated | TTL isolation,12V non isolated,24V PLC isolation | |

| Power output | 12VDC | |

| Trigger level | 5V,12V,24V | |

| Speed measurement range | (1)Against proximity switch,PLC,speed range:0 ~ 20000 RPM. (2)Against high speed encoder,incremental encoder,shaft encoder,speed range:0 ~ 10000 RPM,impulse per circle:1-2048. | |

| precision | ±0.5% | |

| Sway channel(optional for wind turbine tower measurement, sensor model RH123) | ||

| Channel No. | 1 channel,two axial | |

| Signal range | 0~5V | |

| Processing channel(optional) | ||

| Channel No. | 2 channels | |

| Input impedance | voltage:≥ 10kΩ current:≤ 250Ω | |

| Signal access | voltage:-10V ~ 10V current:4mA ~ 20mA | |

| precision | ±0.5% | |

| Signal processing | ||

| Acquire long time waveform length | 2M samples/CH | |

| Acquire measurement definition length | 1K,2K,4K,8K,16K,32K,64K,128K,256K | |

| Spectrum lines | 400,800,1600,3200,6400,12800,25600,51200,102400 | |

| Basic parameter | ||

| CPU frequency | 400MHz | |

| Data storage | RAM:64M Bytes,Flash:standard 1G Bytes | |

| Internet | TCP/IP,10/100baseT,optical fiber(optional) | |

| communications | RS485,default 1 channel(2 channels max.) | Hardware support for oil and inclinometer incidence sensor access |

| Using condition | ||

| Dimension | 400mm×300mm×110mm | |

| Weight | <5kg | |

| IP Grade | IP65 | |

| Working environment | -40~70ºC,≤95%RH,non-condensing | |

| Storage environment | -50~85ºC,≤95%RH,non-condensing | |

| atmospheric pressure | 70kPa ~110kPa | The highest altitude is 3000 meters |

| Power supply | ||

| Working voltage | Outdoor: 220VAC±20%,50~60Hz Indoor: 12-24VDC | Need to replace transformer to support 85~135VAC |

| Consumption | <8W | |

| Certification | ||

| Certificate | CE | |

| Immunity to electromagnetic interference | ||

| ESD immunity | EN61000-4-2 4 level ±8kV(contact discharge) ±15kV(air discharge) | |

| Radio frequency electromagnetic radiation immunity | EN61000-4-3 3 level 10V/m | |

| EFT immunity | EN61000-4-4 4 level ±4kV | |

| Surge immunity | EN61000-4-5 4 level ±4kV | |

| radio frequency transmission immunity | EN61000-4-6 3 level 10V | |

| Magnetic field immunity | EN61000-4-8 5 level 100A/m | |

| Impulse magnetic field immunity | EN61000-4-9 5 level 1000A/m | |

| Damped oscillation field immunity | EN61000-4-10 5 level 100A/m | |

| Voltage drop, interrupt, and voltage fluctuation immunity | EN61000-4-11 60% rated voltage 10 cycles | |

MOS3000 Software

Site Installation

Industrial Plants

Wind turbines

Certificate

Ronds

30 professional vibration analysts

Diagnosis experts with more than 20 years of experience

CAT III vibration analysts

CAT II vibration analysts

Intelligent Algorithm--big data team

Algorithm team with 11members, led by famous doctoral tutor

Big data team with 13 members

Remote Diagonistic Center and Lab

Contact

Kelly Xu

Web: ronds5335195.en.made-in-china.com